In recent years, as Europe has strengthened its environmental protection and safety standards, some traditional chemicals—particularly certain photoinitiators used in UV curing and photopolymerization processes—have been increasingly restricted or banned.

So how about the photoinitiator TPO?

As we all know, the proportion of initiators in the entire solid system is not very high, about 2% to 5%. However, it plays a key role in the film formation of prepolymers. According to the current initiators in the market, it is divided into two types, one is for UV thermal light source, UV mercury lamp. For short-wave absorption is relatively strong initiators, the representative is the photoinitiator 1173 and 184, the other is phosphine oxide, the absorption of long wave is relatively strong, because LEDUV this light source, its wavelength, its main band in 365nm, 395nm 405nm and so on these long waves. One such representative is TPO.

TPO has biological toxicity mainly in the following two aspects. First, photoinitiators are mainly compounds belonging to the subclass. This small molecule compound is formed after the film. There may be residues of this substance, which may migrate to the packaging. After the surface of the solidified material, if we use it to carry out a packaging, especially some packaging of food, it may contaminate these foods, and eventually pose a certain threat to human consumption. Another point, because of the free radicals that are produced by the initiator. Its process is produced by cracking and has the potential to produce smaller compound molecules that can be biotoxic. After a large number of experiments have been reported, suspected to have reproductive toxicity and skin irritation substances. As a result, it has been placed under stricter regulatory control in some European countries.

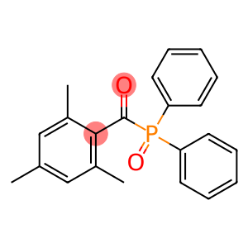

This has led to an urgent need for alternative photoinitiators that can provide similar performance but with fewer environmental and health risks. Photoinitiator TMO (2,4,6-trimethylbenzoylphenylphosphine acid ester) has emerged as a promising replacement due to its superior performance and relatively lower environmental impact.

At the same time, there are many alternatives, such as our company currently sells a lot of TMO,TPO-L and BAPO.This article will focus on the TMO.

Advantages of Photoinitiator TMO

1. Environmental Friendliness and Low Toxicity

Compared to TPO, TMO poses significantly lower risks to the environment and human health. Research indicates that TMO degrades more quickly in aquatic environments and has minimal toxicity to aquatic life and microorganisms. Additionally, TMO has low skin irritancy and toxicity, meeting Europe’s stringent safety standards and fulfilling both environmental and health protection requirements.

2. Excellent Photoinitiation Performance

TMO demonstrates outstanding performance in UV-curing applications, efficiently initiating the photopolymerization process. It offers faster curing times and improved production efficiency, especially under low-energy light sources. Furthermore, TMO exhibits good activity across a wide range of UV wavelengths, making it adaptable to various light sources.

3. Low Volatility and High Stability

TMO features low volatility and migration, ensuring higher chemical stability during use. Even in coatings or inks, TMO remains stable and reduces potential migration issues, enhancing the durability and safety of the final product.

4. Good Process Compatibility

TMO is highly compatible with existing processes and can serve as a direct replacement for TPO without requiring significant changes in production methods. This compatibility reduces production costs and technical adjustments for manufacturers, making it a practical and cost-effective solution.

Prospects for the application of TMO as a substitute for TPO

The low environmental impact and efficient light initiation of Tmos make them an attractive alternative as TPO becomes more and more constrained.TMO has great potential in various industries, such as uv curing coatings, electronic components encapsulation and flexible printing ink.

1. Paint industry

Uv-curable coatings, widely used in industries such as automotive, home appliances and furniture, benefit from TMO's ability to improve adhesion and hardness.In addition, TMO helps to reduce volatile organic compound (VOC) emissions, in line with strict European environmental regulations.

2. Ink industry

In flexographic printing and other UV-curable ink applications, TMO's efficient curing properties and low mobility make it an ideal choice.As consumer demand for environmentally friendly products grows, TMO is likely to become a popular choice for the ink industry.

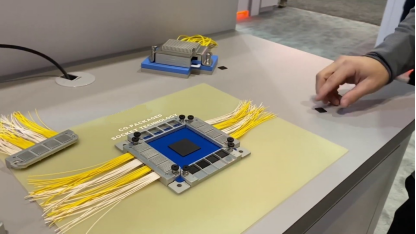

3. Electronic packaging and optoelectronic materials

TMO also has a wide range of applications in electronic packaging and optoelectronic materials.With high efficiency and stability in UV curing, TMO can improve the reliability and durability of electronic components.

Kindchem is a leading supplier of photoinitiators like TPO,TMO,BAPO,TPO-L, offering a wide range of products to meet the diverse needs of industries such as coatings, adhesives, inks, and 3D printing.

Kindchem also provides a variety of related photoinitiator products, each designed to offer optimal performance in different curing systems.

Our products meet the highest industry standards, ensuring reliability, environmental safety, and consistent quality, helping customers improve manufacturing efficiency and product performance.